By Tom Frantz

The almond harvest finished this year a few days earlier than normal in mid-October. As usual, this activity produced a horrible 10 weeks of choking dust for many San Joaquin Valley residents. The young, the elderly and those who play or work outside are most at risk from the serious health effects brought on by this airborne blanket of fine particles.

Two-thirds of the population is especially sensitive to this seasonal brown haze, which covers the entire Valley floor for weeks on end. This muck causes asthma attacks, sinus headaches and lung congestion. Just as the flu season begins, this additional lung torturing dust is added to the most polluted air in the nation.

It is estimated that around 40 pounds of dust are emitted from every harvested acre of almonds. With close to 850,000 acres of almonds in the San Joaquin Valley, there are more than 200 tons of dust blown into the air every day during the 70‒75 days of the harvest.

This dust is measured officially by the San Joaquin Valley Air Pollution Control District (Air District) as PM10. This is defined as particulate matter of 10 microns or less. The levels of PM10 are highest in the fall and winter months. In the fall, it is directly emitted dust particles that form the bulk of this pollution. In the winter, it changes to mostly secondary particles formed from gaseous mixtures of ammonia from dairies and nitrous oxides from engine and boiler exhaust.

Almond acreage in California is growing rapidly. Around 300,000 acres of almonds have been added over the past 10 years in the San Joaquin Valley. Each year, we are seeing more dust in the air from the almond harvest. Almonds have replaced crops like cotton and barley, which only emitted about 10% as much dust per acre during their harvest.

Measurements by the Air District show that average levels of PM10 increased during August and September. In fact, levels the past few years are approximately 15% higher than they were 10 years ago. Clearly, the fall dust problem is getting worse and increased almond acreage has to be most of the cause.

So, what can be done about this dust besides draconian measures such as outlawing new plantings of almond trees and forbidding mechanized harvest? There are actually a few ways to dramatically improve the situation that would not be cost prohibitive.

The dust comes from three different activities during a typical almond harvest. The trees are first shook violently and dust rises from the leaves. This is about 5% of the problem. After shaking, the nuts are blown and swept into windrows. This puts another 20% of the dust into the air as the dirt on the ground is being moved around by the sweepers. Finally, a full 75% of the problem is the pickup machines. They scoop up the windrows of almonds, which are full of dirt, and forcefully blow the dirt off of the almonds before the nuts are dumped into a trailer and hauled out of the field.

Fortunately, the solution lies in modifications to the sweepers and pickup machines. The sweepers and accompanying berm blowers need fine tuning. The height of the sweeper tines is important so that the nuts are raked but the underlying dirt stays put. The blowers need to be carefully aimed and the force of the air adjusted down to the minimum that gets the job done. Finally, optimum adjustment of the equipment and carefully calibrated speeds through the orchard can cut the number of sweeping passes from three to two. These types of practices will save the farmer some money and reduce the dust from sweeping and blowing by 25%.

The pickup machines are the biggest part of the dust problem, but they are also the easiest to modify in order to greatly decrease the amount of dust generated. Because the pickup machine simply must blow the dust away from the nuts on a conveyor above the ground, it is not a major problem to design equipment that first blows off the dust and then collects the dust and lets it fall to the ground instead of being released as a cloud into the air.

This can be done through a combination of mist sprayers into the dust plume and/or running the dust through a mechanical cyclone that clumps the dust into heavier-than-air particles. Almond pickup machines have been designed to do this quite effectively for several years already. They actually reduce the dust from this phase of the harvest by 75%. Unfortunately, not all machines are sold with this innovation because it is not required and it does add more cost to the equipment.

Reducing the dust from sweeping by 25% and the pickup machine by 75% can reduce the overall dust problem from almond harvesting by at least 60%. It would be quite an improvement that could be phased in over a few years if all new pickup machines sold in California had to have this relatively inexpensive technology. A concerted program by the State Almond Board training sweeper operators about better practices would also be useful. The Air District could play a significant role in incentivizing these improvements with both rules and money.

In conclusion, the dust from the almond harvest needs to be recognized as a public health crisis and the public must demand that the problem be mitigated by the reasonable controls already existing.

*****

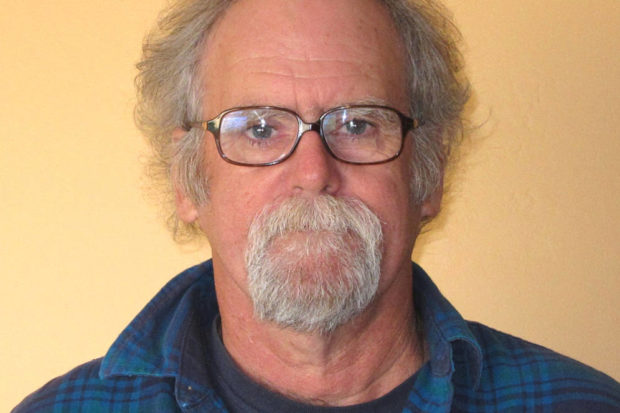

Longtime clean air advocate Tom Frantz is a retired math teacher and Kern County almond farmer. A founding member of the Central Valley Air Quality Coalition, he serves on the CVAQ steering committee and as president of the Association of Irritated Residents. CVAQ is a partnership of more than 70 community, medical, public health, environmental and environmental justice organizations representing thousands of residents in the San Joaquin Valley unified in their commitment to improve the health of Californians. For more information, visit www.calcleanair.org.